Manufacturer & Exporter of Various Process Equipments In Stainless Steel (SS), Heat Exchangers, Reactors, Special Purpose Assemblies

Manufacturer & Exporter of Various Process Equipments In Stainless Steel (SS), Heat Exchangers, Reactors, Special Purpose Assemblies

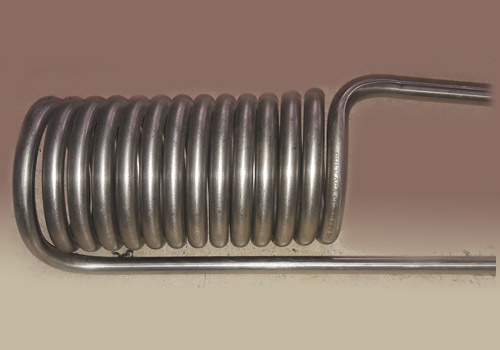

It is a heat exchanger which gives a desired supply of temperature to the end product is fabricated by coiling a 7 meter tube in 7 rotations and is placed in a vessel which is pressurized at the design pressure. It is a basic cooler (heat exchanger) which is used in low vapour pressure systems. It runs on the principle of thermosiphon. The manufacturing is done in various Rating varying from class 300 to class 1500. The complete fabrication is done in-house.

It is a piping system which is manufactured with different kinds of valves and instruments for flushing of fluid to avoid any air intrusions in the final supply of the product. The product manufacturing ranges from class 300 to class 2500 with different kind of materials like SS 316L SS duplex, etc. All the manufacturing is done in house.

Plan 52 comprises of a vessel which is used to keep the fluid in buffer condition at thermosiphon state. The manufacturing is done using an 8” pipe with various schedules. The end connections are flange end or pipe cap rest all necessary nozzle connections are done as per drawings. The vessels are pressurized from 65 kg/cm2 to 700 kg/cm2 the product requires various brought out instruments which are procured from various lists of suppliers. The suppliers are either EIL approved or customer approved. The product rating ranges from class 300 to class 2500. The complete manufacturing is done in house.

Plan 53B comprises of a cooler and bladder accumulator which is used to keep the fluid in buffer condition in the pressurized state. The manufacturing is done with an 8” OD shell with a 7 meter rolled coil inside the shell which cools the working fluid. The manufacturing is done in various materials from carbon steel, SS 316L, SS duplex, Incoloy, etc. This plan requires expertise in piping. The manufacturing is done from class 300 to class 2500 flanges and piping fittings. The coolers used in this plan vary from helix coils to shell and tube heat exchangers.

The plan comprises of a 6" OD vessel with ends connected with a pipe cap (butt welded). The extended nozzle connections are manufactured as per drawings. This plan is used as a leak detection system from the end used product. It is manufactured from materials like carbon steel, stainless steel etc and ranging from class 300 to class 1500 flanges and piping fittings.